Marshalls locks waste carbon in concrete bricks

Posted: Tuesday, May 9th, 2023

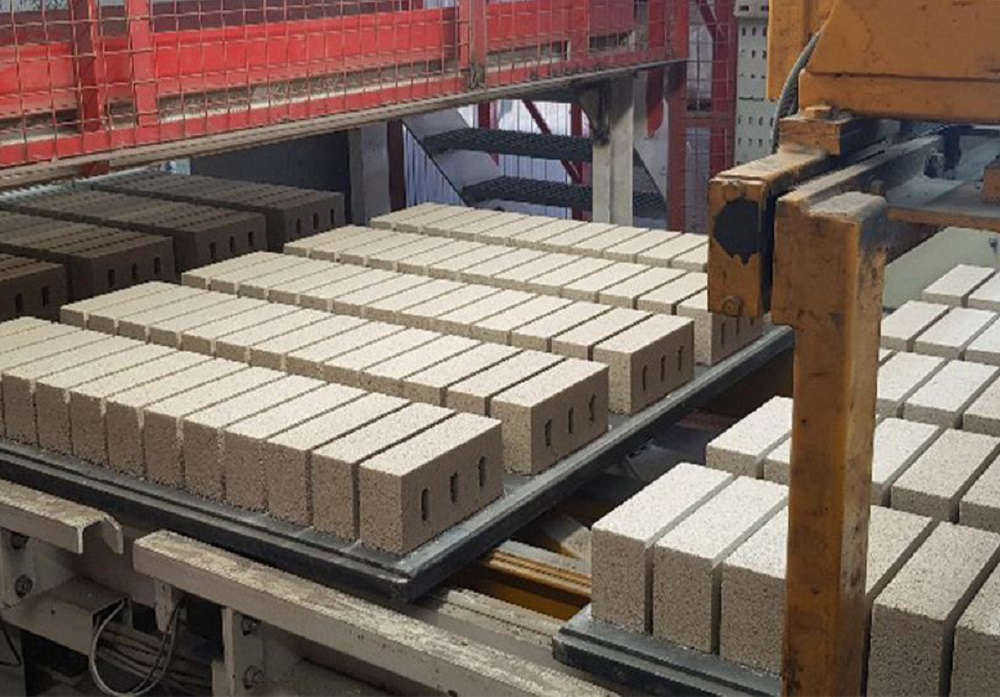

Hard landscaping and building materials supplier Marshalls has announced details of two innovative projects helping it accelerate sustainability plans, Builders Merchants’ News reported. Following announcements of a trial last summer, Marshalls has become the first precast concrete manufacturer in the UK to use CarbonCure technology, a process which permanently locks captured carbon into concrete. The innovative technology is being used on facing bricks manufactured at the Marshalls plant in Grove, South Wales where around 50 million bricks are made each year. The carbon is injected into the brick during the manufacturing process and it has no impact on its performance or appearance. Nick Jowett, technical director at Marshalls, said: "We’re continually testing and trialling product and manufacturing innovations, and to be able to introduce something which also has a sustainability benefit is a double win. "While our customers will see no difference in our products look and performance, we expect that, from this manufacturing site alone, we’ll prevent 30 tonnes of carbon from entering the atmosphere every year. This is the equivalent of driving a family car nearly five and a half times around the world.” CarbonCure is a climate tech company offering a suite of technologies that reduce and remove carbon dioxide across the concrete manufacturing process. CarbonCure’s technologies inject CO2 directly into concrete as it is being mixed. The CO2 immediately reacts with cement in the mix and mineralises to create calcium carbonate (CaCO3). Once the CO2 is mineralised, it is permanently locked into the concrete forever — never to be released into the atmosphere, even if the concrete is demolished. Another project set to support Marshalls in its sustainability mission and transform the carbon footprint of a much-specified material is the development of cement-free concrete. Marshalls’ technical experts have been working on several avenues for this for some time, and late last year, the company produced its first full-scale production run of cement-free concrete blocks. Michael Edwards, group head of sustainability at Marshalls, said: “Cement can account for over 80% of the total carbon footprint of a concrete product, so it’s no surprise that customers have been asking for cement-free materials for a while. "However, as a business known for its high-quality materials, we need to ensure that in removing the cement, we’re not compromising on the quality, appearance or longevity of our products - so we’re refining the materials and process before a full launch later in 2023.”

Trending Stories

-

Essex electrician has roundabout signs rejected

Essex electrician has roundabout signs rejected

A sparkie’s bid to sponsor signs on two roundabouts has been refused by planning chiefs who described them as “clutter”

-

Barbie caused a ‘worldwide’ shortage of pink paint

Barbie caused a ‘worldwide’ shortage of pink paint

Barbie needed so much fluorescent pink paint that it caused a worldwide supply shortage for an entire company

-

Builders find body of man murdered in the 1960s and buried in back garden

Builders find body of man murdered in the 1960s and buried in back garden

A woman who bought a South London house was left horrified after builders discovered the body of a man murdered in the 1960s and buried in her garden 14 months after she moved in

-

'Government insulation scheme ruined my home'

'Government insulation scheme ruined my home'

A home-owner said his flat has been ruined by black mould caused by a government "green" insulation schem

-

Builder celebrates lottery win by buying his coworkers bacon butties

Builder celebrates lottery win by buying his coworkers bacon butties

A builder from Milford Haven who won big on the lottery celebrated his victory by treating all his workmates to a round of bacon rolls

Comments

Add a comment